TPO (Thermoplastic Olefin), EPDM (Ethylene Propylene Diene Monomer), and PVC (Polyvinyl Chloride) are three common types of single-ply roofing membranes used in commercial and industrial applications. Each material has its own set of characteristics, advantages, and considerations. Here’s a brief overview of each:

- TPO (Thermoplastic Olefin):

- Composition: TPO is a blend of polypropylene and ethylene-propylene rubber. It often includes reinforcing materials like polyester or fiberglass.

- Installation: TPO roofing is typically installed using heat welding or hot-air welding methods, creating strong seams.

- Color Options: TPO is available in reflective white and light-colored options, contributing to energy efficiency by reflecting sunlight.

- Flexibility and Durability: TPO is known for its flexibility, resistance to punctures, and durability against UV radiation, chemicals, and ozone exposure.

- Cost: Falls within a moderate price range, making it competitively priced.

- EPDM (Ethylene Propylene Diene Monomer):

- Composition: EPDM is a synthetic rubber roofing membrane composed of ethylene, propylene, and diene monomers.

- Installation: EPDM is typically installed using adhesive or ballasting methods. Seams are adhered with special seam tapes or adhesives.

- Color Options: Traditionally available in black, but white EPDM is also an option. Black EPDM may absorb more heat, while white EPDM reflects sunlight.

- Flexibility and Durability: EPDM exhibits good flexibility and elasticity, making it suitable for temperature fluctuations and thermal shock.

- Cost: Considered cost-effective, especially for larger roof areas.

- PVC (Polyvinyl Chloride):

- Composition: PVC roofing membranes are made from polyvinyl chloride, a type of plastic.

- Installation: PVC roofing is typically installed using hot-air welding methods. The seams are heat-welded for a strong and watertight connection.

- Color Options: PVC comes in various colors, including white, tan, and gray. White PVC is popular for its reflective properties.

- Flexibility and Durability: PVC is known for its flexibility, chemical resistance, and durability against UV exposure. It is also resistant to punctures.

- Cost: PVC roofing tends to be on the higher end of the price scale compared to TPO and EPDM.

When choosing between TPO, EPDM, and PVC roofing, factors such as installation method, color preferences, climate considerations, budget constraints, and specific project requirements play a significant role. Each material has its strengths, and the selection should be based on the unique needs of the roofing project.

As a building owner whose primary concern is cost and longevity, the most important characteristics of TPO, EPDM and PVC are:

- TPO (Thermoplastic Olefin):

- Cracking: ASTM (American Society Testing Materials) has required TPO to be reformulated 3x due to premature cracking. Sika Sarnafil, one of the world’s most respected material manufacturers, has comprehensive information detailing these issues at https://usa.sika.com/sarnafil/en/why-sika-sarnafil/tpo-failures.html

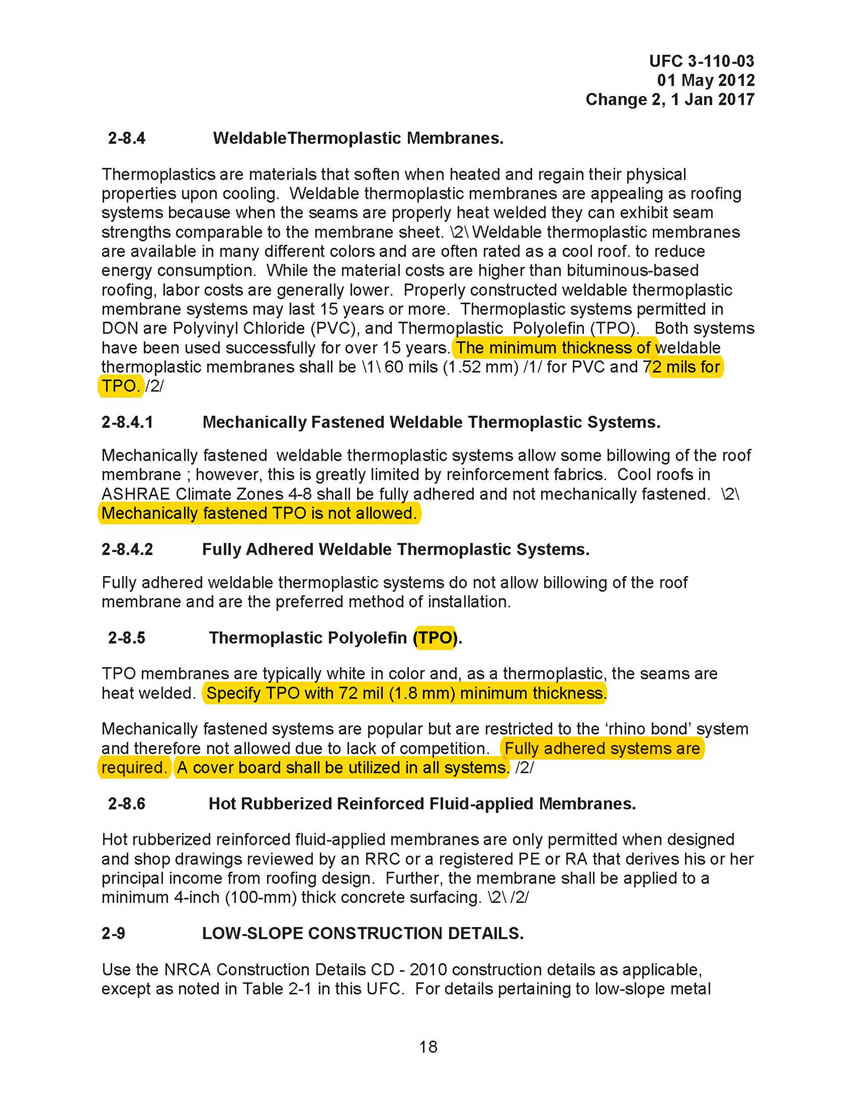

- Temporary: The United States government, who has more flat roofs than anybody else, considers most TPO installations to be temporary roofs lasting 10 YR or less. For a TPO roof to be considered a conventional roof is must be (i) minimum of 72 mils thick, (ii) fully adhered (it is not strong enough to be mechanically attached), (iii) and a coverboard must be used per the UFC (Unified Facilities Criteria) 3-110-03:

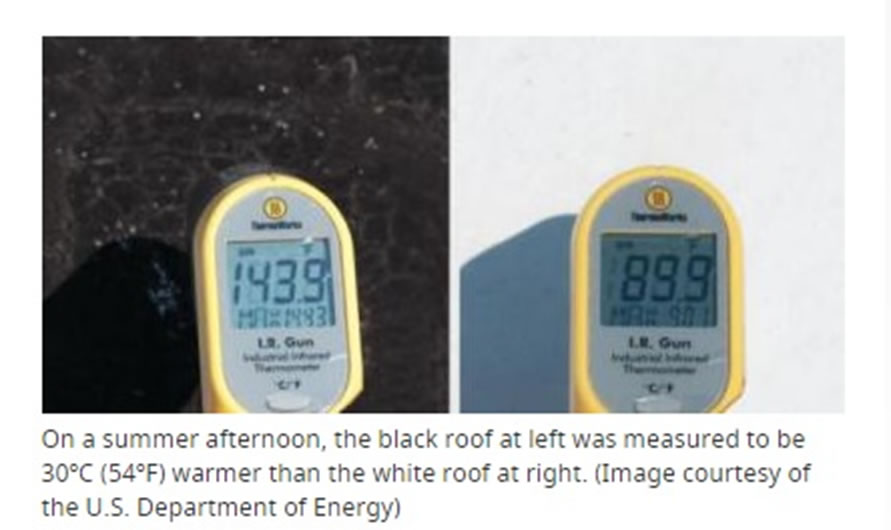

- Hot: White EPDM is available only a small % installed is white due to cost and the white color just being on the surface. Most EPDM absorbs approximately 95% of the sun’s UV rays and in the summer is approximately 50° hotter than the air temperature making HVAC equipment run longer to cool the building or just making the inside of the building hotter:

PVC (Poly Vinyl Chloride)

- Longevity: PVC has had the same formulation for over 50 YR

- Durability: Sarnafil, the oldest manufacturer of PVC commercial flat roofing systems has been proven to last for decades on facilities as diverse as high rises, museums, retail stores, sports arenas and schools with numerous roofs that are currently over 35 years old and still performing: https://usa.sika.com/sarnafil/en/why-sika-sarnafil/oldest-roofs.html

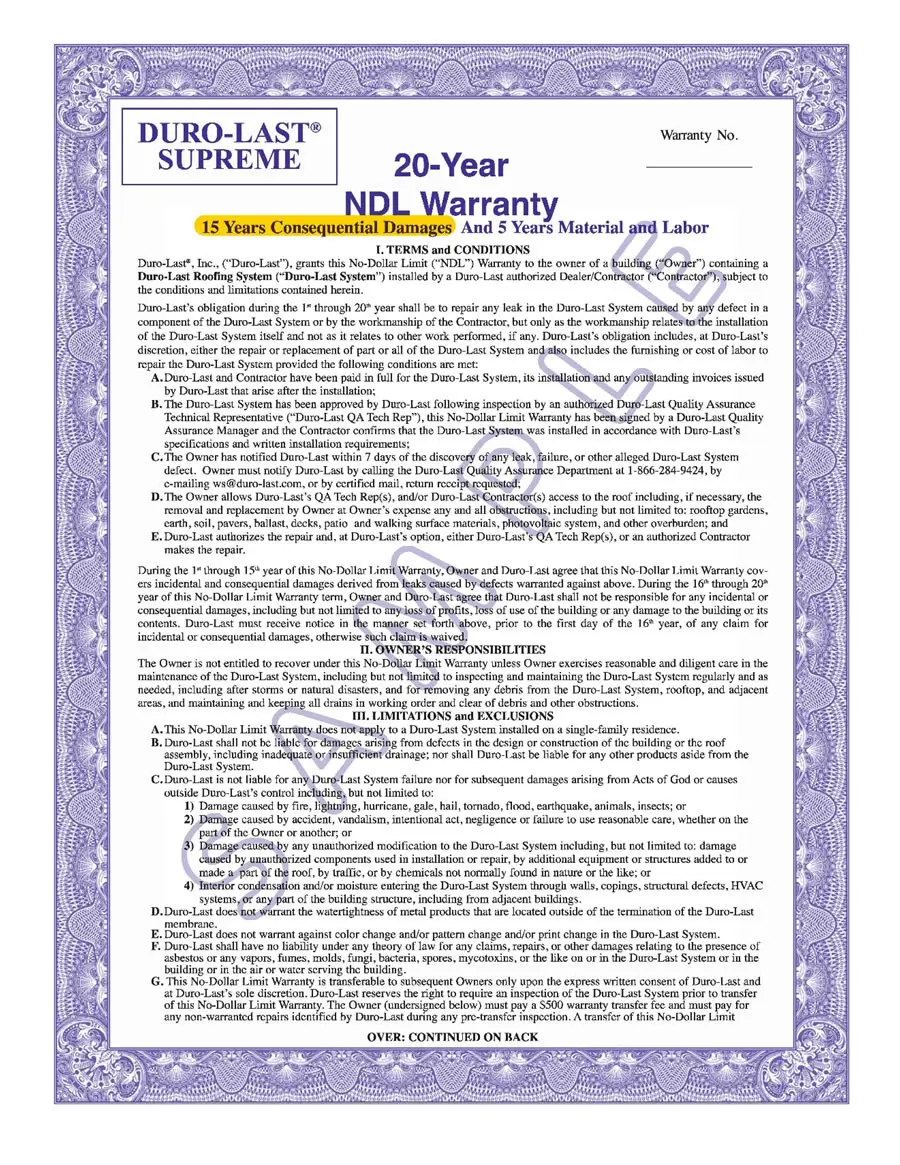

- Warranty: Duro-Last PVC is custom pre-fabricated for each roof and is the only commercial flat roofing system to have a consequential damages warranty that covers damages to a building from a roof leak: